Busbar Jointing Methods/ شیوه های اتصال باسبار و شینه های مسی در تابلوهای برق

شیوه های اتصال باسبار و شینه های مسی در تابلوهای برق

اتصال شینه های مسی در تابلوهای برق بایستی از لحاظ مکانیکی قوی و مقاوم در برابر اثرات محیط باشد.

میتوان با استفاده از پیچ کردن ، اتصال کلمپی ، اتصال با پرچ و لحیم و جوشکاری به سادگی شینه ها را به هم متصل کرد . در این بین روش های اتصال با پیچ و اتصال کلمپی پر استفاده تر هستند .

1- اتصال با پیچ

در این روش اتصال با پیچ در محل هم پوشانی شینه های برقرار میشود .

این نوع اتصال قابل اطمینان بوده و فضای زیادی را اشغال نمیکند.

اما نیازمند سوراخ کاری و پانچ بر روی هادی ها هستند که میتواند موجب اعوجاج و غیر یکنواختی جریان شود.و همچنین فشار یکنواخت کمتری نسبت به اتصال کلمپی دارند ، با این حال این نوع اتصال بسیار متداول است.

2- اتصال کلمپی

این نوع اتصال در محل هم پوشانی شینه ها و با استفاده از یک کلمپ خارجی در محل همپوشانی ایجاد میشود.

این نوع اتصال در صورت طراحی صحیح فشار یکنواختی ایجاد کرده و مونتاژ آسانتری دارند.

3- اتصال با پرچ

4- لحیم وجوشکاری

Busbar joints are of two types; linear joints required to assemble manageable lengths into the installation and T-joints required to make tap-off connections. Joints need to be mechanically strong, resistant to environmental effects and have a low resistance that can be maintained over the load cycle and throughout the life of the joint.

Busbar Jointing Methods

Efficient joints in copper busbar conductors can be made very simply by bolting, clamping, riveting, soldering or welding. Bolting and clamping are used extensively on-site. Shaped busbars may be prefabricated by using friction stir welding.

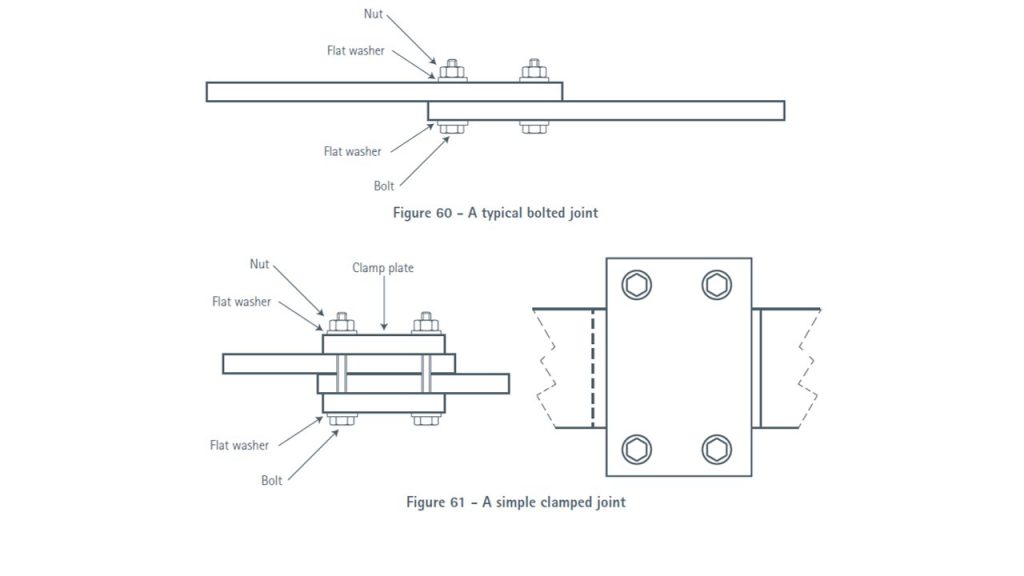

Bolted joints are formed by overlapping the bars and bolting through the overlap area. They are compact, reliable and versatile but have the disadvantage that holes must be drilled or punched through the conductors, causing some distortion of the current flow in the bar. Bolted joints also tend to have a less uniform contact pressure than those made by clamping but, despite these issues, bolted joints are very commonly used and have proven to be reliable. They can be assembled on-site without difficulty.

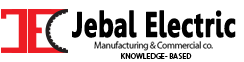

Clamped joints are formed by overlapping the bars and applying an external clamp around the overlap. Since there are no bolt holes, the current flow is not disturbed resulting in lower joint resistance. The extra mass at the joint helps to reduce temperature excursions under cyclic loads.

Well-designed clamps give an even contact pressure and are easy to assemble, but take up more space than a bolted joint and are more expensive to manufacture.

Riveted joints are similar to bolted joints. They can be efficient if well made; it is difficult to control the contact pressure. They cannot easily be dismantled or tightened in service and they are difficult to install.

Soldered or brazed joints are rarely used for busbars unless they are reinforced with bolts or clamps since heating under short-circuit conditions can make them both mechanically and electrically unsound.

Welded joints are made by butting the ends of the bars and welding. They are compact and have the advantage that the current-carrying capacity is unimpaired, as the joint is effectively a continuous copper conductor. However, it may not be safe or desirable to make welded joints in situ.

*[” Copper for Busbars – Guidance for design and installation”, David Chapman & prof. Toby Norris]

دیدگاهتان را بنویسید